Anodizing titanium rings: Techniques and benefits

A few weeks ago, I did some anodizing on the titanium rings of my NFC 661 HM and decided to make a tuto for those interested.

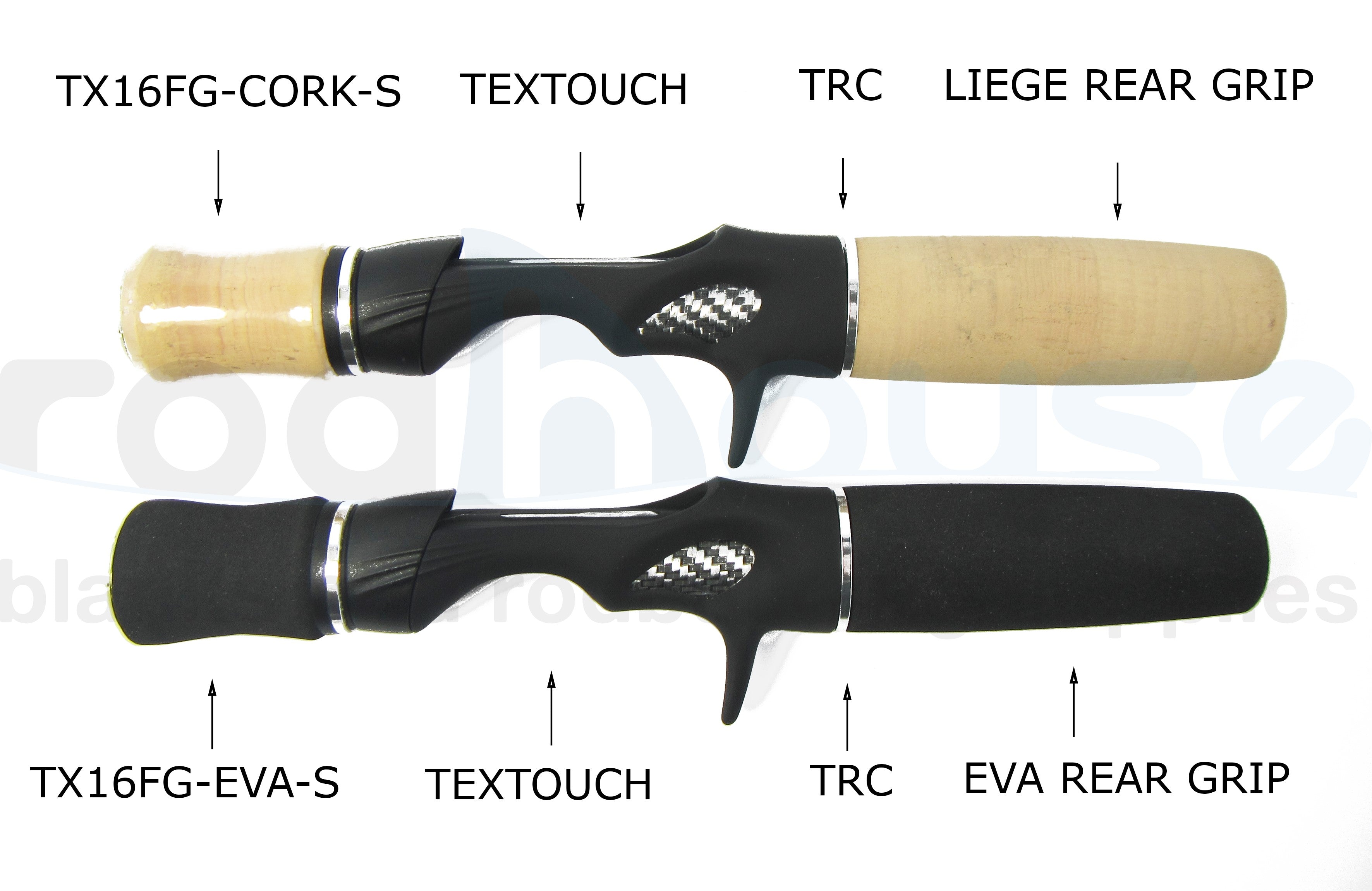

First of all, you need to know that titanium anodizing is a surface oxidation (creation of titanium dioxide by electrolysis). It is therefore a reversible operation, and all you have to do is remove this thin layer of oxidation to restore the original appearance. This can be done by sanding (although I don't recommend this for rings) or polishing. This operation isn't always straightforward, because while polishing a KL20 is possible, doing it for a KT4 is a different matter.

And as the coating can be removed by polishing, regular friction of the rings with something will have the same effect. This effect can therefore fade over time.

How do colors work?

The principle of anodizing comes from the fact that titanium dioxide produces interferential colors, i.e. the color depends on the thickness of the oxide layer. It is the high refractive index of titanium dioxide that enables this phenomenon.

Varying the voltage used during electrolysis is enough to modify the thickness of this oxide layer, and therefore, vary the color.

We can therefore change the color if we don't like it, using a higher voltage. On the other hand, if we want a color with a lower tension, we have to repolish the part before starting the process again.

How to do an anodizing

Here is a list of the Necessary equipment:

- sulfuric acid

- a container (glass or Inox)

- a stainless steel spoon if the container is glass

- flexible electrical wire, with crocodile clips

- 9V batteries or, best of all, a stabilized laboratory power supply (but 0-75V or 100V supplies are hyper-expensive... but perhaps you have access to such tools at your work?)

- titanium parts, in this case, rings .

First, connect the "-" and "+" poles of the 9V batteries (or power supply) to the Inox spoon (or container) and the titanium ring. If you have crocodile clips, it's easy.

I took a 9V battery plug, cut it out and soldered it to 2 wires. It goes like this:

Then, in the container, I mix about half sulfuric acid, half water, and dip my stainless steel spoon, connected to the negative pole of my battery. If you're using an Inox container, you connect the battery directly to the container.

Then the positive pole to my titanium ring (here, I didn't have a ring for the photos, so it's a piece of titanium).

All that's left to do is dip the ring in the acid solution, and coloring takes place instantly. The anodizing takes effect.

ATTENTION: Don't dip the whole ring, the plug (crocodile or other) that's connected to the positive pole must not touch the acid solution, otherwise it makes sshhhrrriiiqqqqqq ...

Once soaked, rinse the piece well under running water, dry, and voila!

To vary the voltage using 9V batteries, simply connect them in series (9, 18, 27, 36, etc...).

And that's it, I'm done!

I confess I tried to make purple on my rings (75V) but with 9V batteries, it's not great. I'm sure that with a stabilized power supply, I would have had a better result!

I made several attempts and polishes to finally settle on this purple-blue...

NDLR:anodizing doesn't work on titanium tip rings, probably due to a slightly different alloy.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.